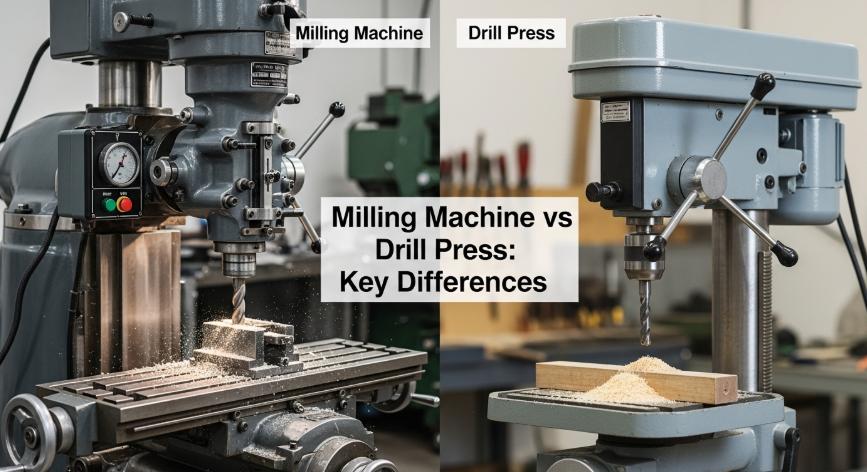

Businesses need to make an important choice between milling machines and drill presses for their machining work. The two machines serve different purposes because they have different designs and operational features, which lead to different manufacturing uses. Manufacturing organizations and engineering teams need to understand these differences to achieve better production results and maintain precise machining standa

A milling machine is known for its versatility and ability to perform complex cutting operations. A drill press is primarily used for straightforward hole-making tasks. The selection of an inappropriate machine results in operational hindrances. It also increases expenses and decreases production capacity. This comparison highlights the operational differences and structural distinctions, and performance characteristics that separate milling machines from drill presses.

Users can evaluate the advantages of their solution by evaluating their design elements, operational methods, and their respective production advantages. The two machines do not have one operating system that outperforms all others. The two systems exist to fulfill particular requirements based on the specific operational conditions.

A milling machine operates as a precise machining device that uses rotating cutting tools with multiple points to remove material from a workpiece. Milling machines possess the capability to execute various tasks. It includes precision cutting of slots, surface shaping and contouring, and accurate drilling execution

The workpiece requires mounting to a movable table system. It enables precise control of its movement across various axes. The milling machine provides essential flexibility to industries that need to produce complex geometric shapes with tight tolerance levels and consistent results.

Milling machines are available in several configurations to meet different production needs. The main categories of milling machines consist of:

1. Vertical milling machines.

2. Horizontal milling machines.

3. Universal milling machines.

CNC milling machines operate through advanced technology, achieving higher accuracy levels while enabling automated operations. It makes them perfect for manufacturing processes that require both high production rates and precise results. The spindle orientation, application complexity, and material requirements determine the design specifications that dominate each machine type.

A milling machine has core components, which include the base, column, spindle, table, saddle, and control system. The base structure of the machine provides complete support to all its parts. The column section contains the spindle operating system. The worktable allows movement in multiple directions, enabling precise machining. The strong construction of this tool maintains stability during extensive cutting tasks.

A milling machine is preferred in manufacturing environments where precision, flexibility, and machining complexity are critical. Milling machines allow operators to perform multiple machining operations through their advanced technology. It enables face milling and slot cutting, contouring, and drilling tasks to be completed without changing equipment. Its multiple functions make it ideal for manufacturing parts that require precise dimensions according to exact specifications.

Milling machines enable operators to achieve precise surface finishes and accurate geometric shapes through their control features. It also regulates cutting depth, feed rate and tool movement. The multi-axis system of the milling machine permits operators to execute machining operations from various angles. These are necessary when creating intricate industrial components.

CNC milling machines provide modern manufacturing facilities with high accuracy and reliability. It makes them suitable for prototype development and mass production. The milling machine serves as a reliable machining solution because it delivers precise and trustworthy performance over an extended period.

|

Aspect |

Advantages |

Disadvantages |

|

Precision |

The system needs to achieve both precise results and precise measurement limits. |

The system demands advanced operation skills. |

|

Versatility |

The system performs several machining tasks at once. |

The system needs more money to buy at the beginning. |

|

Productivity |

The system works best for producing both detailed items and large quantities. |

The system needs more area than it currently occupies. |

|

Automation |

The use of CNC technology leads to better product quality. |

The system requires more money for upkeep than usual. |

The operates as fixed equipment that creates precise, unchanging holes in various materials. The device relies on a fixed sp drill pressindle and an adjustable worktable to produce precise straight drilling instead of relying on handheld drills.

The machine applies controlled vertical force, making it ideal for repetitive hole-making tasks in metal, wood, and plastic materials. The drill press functions as a standard tool for workshops, maintenance spaces, and light manufacturing sites that need accurate drilling without requiring complicated machine operations.

Drill presses come in various types, which differ in their size and power and their intended uses. The common types of this product are:

1. Benchtop drill presses.

2. Floor-standing drill presses.

3. Radial drill presses.

4. Magnetic drill presses.

Small workshops need benchtop models, which work best for their less demanding projects. Floor-mounted drill presses provide more power and greater capacity to handle larger tasks. Radial drill presses enable users to reach distant spots and work with heavy materials.

A drill press structure includes its base, column, worktable, spindle, chuck and motor as its vital parts. The base provides stability, while the vertical column supports the spindle assembly.

The adjustable worktable allows height and angle positioning for accurate drilling. The spindle holds the drill bit and moves vertically to perform drilling operations. The design provides durability and simple operation while maintaining accurate drilling throughout its lifespan.

The drill press provides the ideal solution for tasks that need both exact hole placement and easy operational procedures. The system uses a vertical spindle. A stable worktable to achieve precise drill bit positioning, which creates neat and consistent holes.

The system allows users to maintain precise control. It decreases the risk of both misalignment and material damage during drilling work. The drill press provides better control over depth and maintains pressure at a constant level. It enhances machining results while reducing operator fatigue. The system offers reliable performance, which functions effectively in workplaces that do not require sophisticated programming or complicated installation.

The direct design of a drill press enables users to spend less money on buying, maintaining and operating the machine. A drill press provides small-scale production operations with accurate and effective yet cost-effective machining capabilities.

|

Aspect |

Advantages |

Disadvantages |

|

Precision |

The device produces holes that maintain both their straightness and their uniformity. |

The system can operate only in vertical directions |

|

Ease of Use |

The system requires only basic operation skills, which need minimal time for user training. |

The system lacks the ability to execute advanced machining procedures. |

|

Cost |

The system provides cost advantages because it requires less money for both initial expenses and ongoing operational costs. |

The system provides fewer operational capabilities when compared to milling machines. |

|

Maintenance |

The system requires less effort to maintain while it delivers operational capabilities that span a long period of time. |

The system has restricted capabilities for automated tasks while it maintains limited operational adaptability. |

The two machines differ mainly because milling machines remove materials through their specific design and operational functions. Drill presses operate through their distinct structure. The different machine features enable manufacturers to choose their most appropriate equipment for specific work applications.

|

Aspect |

Milling Machine |

Drill Press |

|

Structure and Design |

The structure has been built to withstand heavy tasks while it supports multi-directional movement through its rigid frame. It enables advanced cutting operations. |

The equipment features a basic vertical design. It includes an unmovable spindle to enable direct vertical drilling operations. |

|

Compatibility |

The system supports multiple cutting tools and materials, which include both complex materials and extremely hard metals. |

The system has restricted compatibility, which allows users to drill through basic materials only. |

|

Price |

The product needs more money for the initial purchase because of its advanced technical design and manufacturing capabilities |

The product offers a lower price point, which makes it suitable for people who need essential drilling tools. |

|

Assembly and Setup |

The system needs people to do precise installation work, while they must maintain correct alignment until professional setup work begins. |

The product enables users to assemble it quickly because it requires only basic installation work. |

|

Maintenance |

The system requires maintenance work because its design includes several parts that move, and it has components that need advanced handling. |

The product requires little upkeep because it contains only essential mechanical components. |

|

Operational Complexity |

The system needs drivers who have either manual control skills or CNC programming competencies to operate the machine |

The system enables users to operate it after they complete a short training program. |

|

Production Capability |

The system provides operational capabilities that enable the precise manufacturing of complex parts and large-scale production. |

The equipment delivers optimal performance when handling basic drilling work, which needs to be done multiple times. |

|

Flexibility |

The system supports multiple operational methods, which create high operational flexibility. |

The equipment restricts its functions to performing drilling tasks and executing basic follow-up work. |

The choice between a milling machine and a drill press should be based on your production needs instead of selecting the more advanced machine. The best solution for you involves three elements: your operational patterns, your available production capacity, and your future business objectives.

Begin by determining which type of work you complete most frequently. The milling machine proves to be the better choice when you need to create complex parts through surface shaping and slot cutting. The drill press becomes the better choice when you need to create holes accurately at a fixed interval.

View the complete range of materials and tools that you will use throughout your project. The milling machines enable users to perform various machining tasks with different cutting tools. Drill presses support only drilling operations and light-duty work.

Decide between using manual controls or automatic systems that provide precise control. CNC milling machines serve as the optimal choice for making precise products that need to be created multiple times. Drill presses function best in environments that require simple tasks without programming needs.

Decision-making depends heavily on available budget resources. The initial costs of milling machines are higher than those of drill presses, which serve as economical options for small shops that handle basic tasks.

You should evaluate all costs, including expenses beyond the initial purchase price. The milling machines generate better financial returns over extended periods because they can handle increasing production demands. Drill presses deliver fast financial returns for businesses that handle consistent, low-volume work.

Your organization should maintain its maintenance requirements and scalability capabilities according to your upcoming business expansion schedule.

Can a drill press replace a milling machine?

No, the drill press functions as a dedicated tool for drilling work. It operates differently from a milling machine that performs various machining tasks.

Is a milling machine more accurate than a drill press?

Yes, the milling machines provide operators with better control over their tools, which results in improved machining accuracy.

Which machine is better for beginners?

The drill press offers operators simplified functions which need minimal technical skills for operation.

Can a drill press be used for light milling?

The procedure should not be done because it presents both structural and safety issues.

Which machine is more expensive?

The initial costs and installation expenses of milling machines exceed those of other machines.

What industries commonly use milling machines?

The automotive industry, aerospace industry, medical field, and precision manufacturing sector.

Are drill presses suitable for production work?

The equipment works best for tasks that require repeated simple drilling.

Which machine requires more maintenance?

The milling machine needs extensive maintenance because its complicated parts require ongoing upkeep.

Can both machines handle metal materials?

The equipment supports all metal types and machine difficulty levels, but milling machines have more advanced operational capacity.

Which option offers better long-term value?

It depends on the application. Milling machines for complex growth, drill presses for stable basic needs.

Both milling machines and drill presses serve important but distinct roles in machining operations. There is no absolute best choice, only the solution that best matches your application, budget, and production goals. Milling machines excel in versatility and precision, while drill presses deliver simplicity and efficiency for focused tasks.

To make the right decision, evaluate your current needs and future plans carefully. If you are seeking reliable, industrial-grade machining solutions, explore advanced milling technologies from CNC Yangsen and choose a structural solution that supports long-term success.