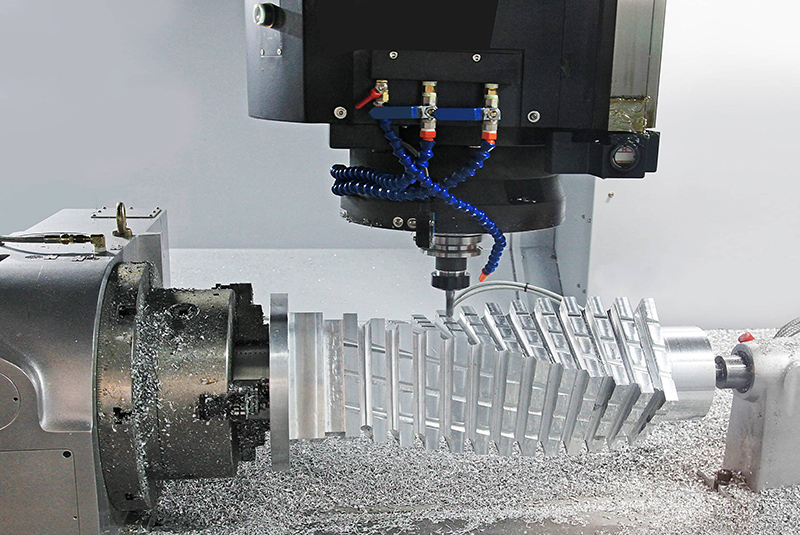

Bei der modernen CNC-Bearbeitung geht es nicht mehr nur um das Schneiden von Metall – es geht um die Effizienz der Maschine.

Da die Bauteile immer komplexer werden und die Produktionszyklen kürzer, stehen die Hersteller vor einer gemeinsamen Herausforderung:

Wie lassen sich Ausfallzeiten reduzieren, ohne die Genauigkeit zu beeinträchtigen?

Manuelle Werkzeugwechsel mögen unbedeutend erscheinen, doch jeder Stopp summiert sich. Jede Unterbrechung stört den Bearbeitungsablauf, verlängert die Zykluszeit und erhöht das Risiko menschlicher Fehler. Daher ist die Automatisierung in modernen CNC-Werkstätten ein logischer Schritt nach vorn.

Hier befindet sich die automatischer Werkzeugwechsler (ATC) Hier kommt der automatische Werkzeugwechsler (ATC) ins Spiel. Durch die Möglichkeit, Werkzeuge während der Bearbeitung automatisch zu wechseln, trägt er dazu bei, dass die Spindel kontinuierlich arbeitet, anstatt zu warten – was gleichzeitig Effizienz, Konsistenz und Flexibilität verbessert.

Doch welchen Nutzen bringt ein automatischer Werkzeugwechsler tatsächlich, und wann ist sein Einsatz sinnvoll?

Das ist genau das, was wir als Nächstes untersuchen werden.

Was genau ist ein automatischer Werkzeugwechsler?

Vereinfacht ausgedrückt ist ein automatischer Werkzeugwechsler (ATC) ein System an einer CNC-Maschine, das während der Bearbeitung automatisch die Schneidwerkzeuge wechselt, ohne den Prozess zu unterbrechen oder einen Eingriff des Bedieners zu erfordern.

Anstatt ein Werkzeug manuell zu entnehmen und ein anderes einzusetzen, wählt die Maschine das benötigte Werkzeug aus einem Werkzeugmagazin aus und tauscht es entsprechend aus. CNC-ProgrammDer gesamte Vorgang läuft in Sekundenschnelle ab – präzise und wiederholt.

Denken Sie an einen typischen Bearbeitungsauftrag: Bohren, Fräsen, Gewindeschneiden, FertigstellenFür jeden Schritt wird ein anderes Werkzeug benötigt.

Ohne automatischen Werkzeugwechsler (ATC) muss die Maschine bei jedem Werkzeugwechsel anhalten. Mit einem ATC arbeitet die Maschine weiter, während die Werkzeugwechsel automatisch im Hintergrund erfolgen.

Kurz gesagt, ein automatischer Werkzeugwechsler verwandelt eine CNC-Maschine von einem Stop-and-Go-Prozess in einen kontinuierlichen, programmierten Arbeitsablauf – genau das, was die moderne Bearbeitung erfordert.

Wie genau verbessert ein automatischer Werkzeugwechsler den Bearbeitungsprozess?

Alles beginnt mit der Automatisierung zum richtigen Zeitpunkt. Wird während der Bearbeitung ein neues Werkzeug benötigt, löst das CNC-Programm automatisch den Werkzeugwechsel aus. Die Spindel gibt das aktuelle Werkzeug frei, der automatische Werkzeugwechsler (ATC) wählt das nächste aus dem Magazin aus, und der Wechsel erfolgt innerhalb weniger Sekunden – ohne den Arbeitsablauf zu unterbrechen.

Alles wird vom CNC-Programm gesteuert.

Werkzeugauswahl, Werkzeugreihenfolge und Werkzeugwechselzeitpunkt sind alle vordefiniert, was bedeutet, dass die Maschine jedes Mal genau weiß, wann und wie sie die Werkzeuge wechseln muss.

Vergleichen Sie dies nun mit dem manuellen Werkzeugwechsel.

Bei manuellen Werkzeugwechseln muss die Maschine anhalten. Ein Bediener greift ein, entfernt das Werkzeug, setzt das nächste ein, überprüft die Position und startet den Prozess neu. Selbst bei sorgfältiger Durchführung entstehen dadurch Ausfallzeiten und kleine Ungenauigkeiten, die sich im Laufe einer Schicht summieren.

Mit einem automatischen Werkzeugwechsler:

Die Maschine läuft ohne manuelle Unterbrechung weiter.

Die Werkzeugpositionierung ist konsistent und wiederholbar.

Die Bearbeitung erfolgt in einem reibungslosen, ununterbrochenen Ablauf.

Das Ergebnis ist ein Bearbeitungsprozess, der sich weniger wie eine Abfolge von Stopps und Starts anfühlt, sondern eher wie ein kontinuierlicher, kontrollierter Vorgang. Allein dieser Unterschied beeinflusst die Effizienz einer CNC-Maschine in der realen Produktion.

Aspekt | Manueller Werkzeugwechsel | Automatischer Werkzeugwechsel |

Werkzeugwechselprozess | Erfordert das Anhalten der Maschine und manuelles Eingreifen | Vollautomatisch, gesteuert durch das CNC-Programm |

Maschinenstillstand | Häufige Stopps zwischen den Bearbeitungsvorgängen | Minimale Unterbrechung, kontinuierliche Bearbeitung |

Werkzeugpositionierung | Hängt von den Fähigkeiten und der Handhabung des Bedieners ab. | Gleichbleibend und wiederholbar in jedem Zyklus |

Workflow-Stabilität | Stop-and-Go-Bearbeitungsprozess | Reibungsloser, programmierter Bearbeitungsablauf |

Beteiligung des Betreibers | Hoher – ständiger Aufmerksamkeitsbedarf | Niedrig – der Bediener konzentriert sich auf Einrichtung und Überwachung |

Produktionseffizienz | Niedriger aufgrund fehlender Schnittzeit | Höher aufgrund reduzierter Leerlaufzeit |

Eignung für komplexe Teile | Begrenzte – häufige manuelle Änderungen verlangsamen den Prozess | Ideal – unterstützt mehrere Werkzeuge in einem Zyklus |

Sobald man die Funktionsweise eines automatischen Werkzeugwechslers verstanden hat, werden die Vorteile sehr praktisch – und sind in der Werkstatt leicht zu spüren.

Der größte Vorteil ist ganz einfach: weniger Warten, mehr Schneiden.

Automatische Werkzeugwechsel reduzieren die Leerlaufzeiten zwischen den Bearbeitungsschritten. Anstatt die Maschine für jeden Werkzeugwechsel anzuhalten, wird die Bearbeitung nahezu nahtlos fortgesetzt, was die Zykluszeiten verkürzt und den Gesamtausstoß – insbesondere bei Aufträgen mit mehreren Bearbeitungsschritten – verbessert.

Die Aufrechterhaltung einer gleichbleibenden Qualität ist schwierig, wenn Werkzeugwechsel von manueller Handhabung abhängen.

Mit einem automatischen Werkzeugwechsler (ATC) werden die Werkzeuge jedes Mal gleich positioniert. Diese Wiederholgenauigkeit reduziert die Abweichungen zwischen den Teilen und trägt dazu bei, eine gleichbleibende Bearbeitungsqualität auch bei längeren Produktionsläufen zu gewährleisten.

Der manuelle Werkzeugwechsel hält die Bediener zwar beschäftigt, aber nicht immer produktiv.

Ein automatischer Werkzeugwechsler reduziert den Aufwand für wiederholte Eingriffe. Die Bediener können sich auf die Einrichtung, die Prozessüberwachung, die Qualitätskontrolle oder sogar den gleichzeitigen Betrieb mehrerer Maschinen konzentrieren, anstatt bei jedem Werkzeugwechsel bereitzustehen.

Präzision bedeutet nicht nur Schneiden – es geht auch um Positionierung.

Ein stabiler, automatisierter Werkzeugwechselprozess minimiert Positionierungsfehler, die durch manuelle Handhabung entstehen. Dies ist besonders wichtig bei engen Toleranzen und Teilen, die mehrere Bearbeitungsschritte in einer einzigen Aufspannung erfordern.

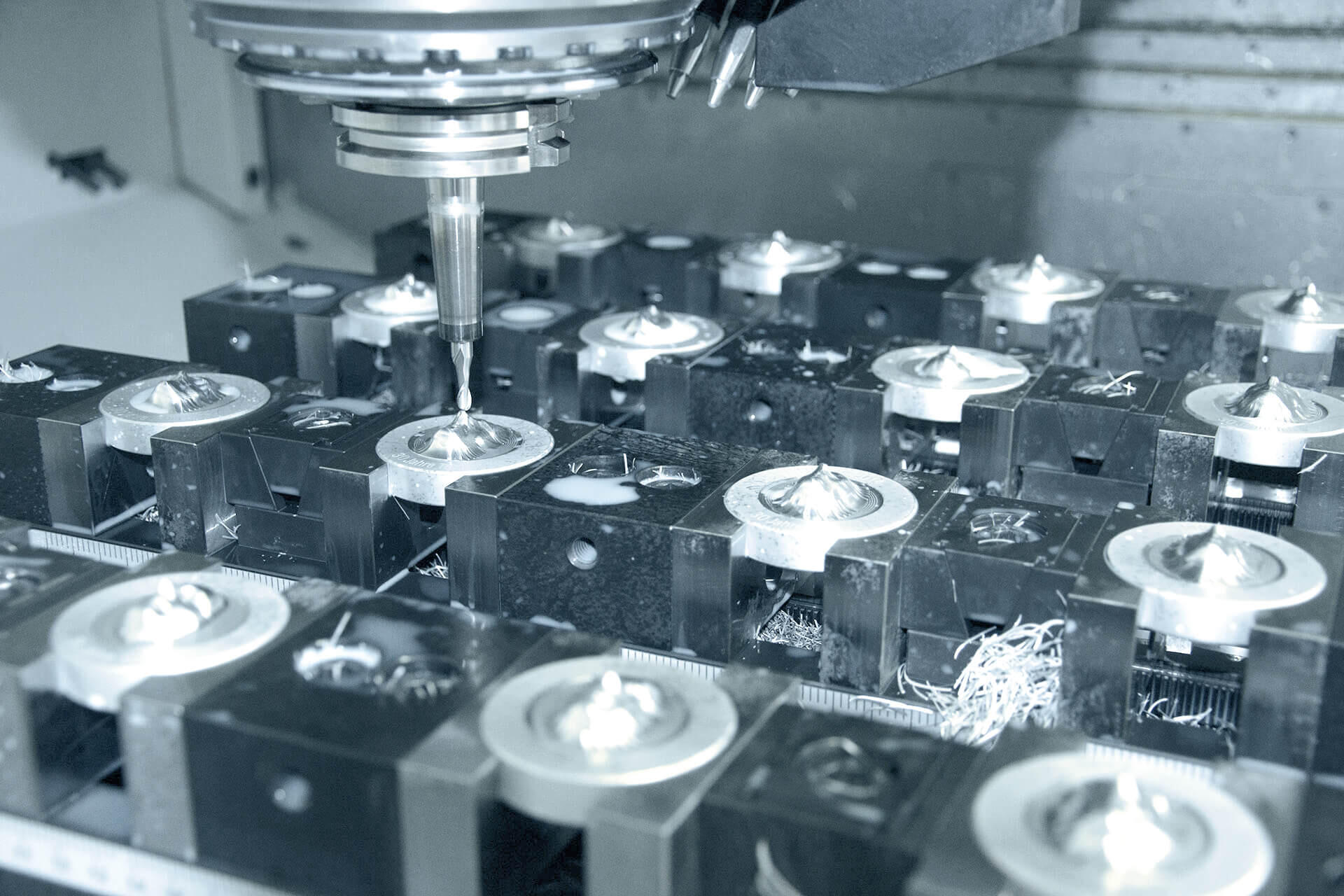

Für komplexe Bauteile wird selten nur ein Werkzeug benötigt.

Ein automatischer Werkzeugwechsler (ATC) ermöglicht den Einsatz mehrerer Werkzeuge – Bohrer, Schaftfräser, Gewindebohrer, Schlichtwerkzeuge – in einem einzigen Bearbeitungszyklus. Dadurch lassen sich fortschrittliche Bearbeitungsstrategien einfacher anwenden, ohne die Maschine anzuhalten oder den Arbeitsablauf zu unterbrechen.

Automatische Werkzeugwechsler bieten zwar klare Vorteile, sind aber keine Universallösung für jede Bearbeitungsumgebung. Wie jede Automatisierungsfunktion bringen auch automatische Werkzeugwechsler Kompromisse mit sich, die man im Vorfeld verstehen sollte.

CNC-Maschinen mit automatischen Werkzeugwechslern sind in der Regel teurer als Basismodelle. Die Mehrkosten umfassen das Werkzeugmagazin, den Wechsler und die Steuerungsintegration. Für Betriebe mit sehr wenigen oder seltenen Werkzeugwechseln ist dieser Aufpreis möglicherweise nicht gerechtfertigt.

Ein automatischer Werkzeugwechsler (ATC) erweitert die Maschine um bewegliche Teile und Steuerungslogik. Moderne Systeme sind zwar zuverlässig, aber dennoch komplexer als manuelle Einrichtungsprozesse. Daher benötigen Bediener und Wartungspersonal grundlegende Kenntnisse über die Funktionsweise des Werkzeugwechslers, um Fehlbedienungen oder Einrichtungsfehler zu vermeiden.

Werkzeugmagazine, Greifer und Wechselmechanismen erfordern regelmäßige Inspektion und Wartung. Späne, Kühlmittel oder eine falsche Werkzeugbeladung können die Leistung mit der Zeit beeinträchtigen. Ein automatisches Werkzeugwechselsystem (ATC) arbeitet optimal, wenn Werkzeugmanagement und Ordnung ordnungsgemäß durchgeführt werden.

Der effektive Einsatz eines automatischen Werkzeugwechslers (ATC) erfordert eine sorgfältige Programmierung. Werkzeugnummern, Offsets und die Werkzeugstandzeitverwaltung müssen im CNC-Programm korrekt organisiert sein. Ohne eine gute Werkzeugverwaltung können die Vorteile des automatischen Werkzeugwechsels beeinträchtigt werden.

Ein automatischer Werkzeugwechsler bietet den größten Nutzen, wenn er optimal auf die Anwendung abgestimmt ist. Für sehr kleine Losgrößen, einfache Arbeitsgänge oder häufige Einzelaufträge kann der manuelle Werkzeugwechsel weiterhin ausreichend – und mitunter sogar wirtschaftlicher – sein.

Ein automatischer Werkzeugwechsler zeigt seinen wahren Wert erst in den richtigen Bearbeitungsszenarien. Es geht nicht um mehr Funktionen, sondern darum, die Maschine optimal auf den jeweiligen Auftrag abzustimmen.

Wenn ein Werkstück in einer Aufspannung gebohrt, gefräst, mit Gewinde versehen und fertig bearbeitet werden muss, summieren sich die Werkzeugwechsel schnell. In solchen Fällen sorgt ein automatischer Werkzeugwechsler für einen reibungslosen Arbeitsablauf und vermeidet wiederholte Stopps, die den gesamten Prozess verlangsamen.

Mit steigendem Produktionsvolumen spielen auch kleine Zeiteinsparungen eine Rolle. Der automatische Werkzeugwechsel reduziert die Nebenzeiten in jedem Arbeitsgang, was sich bei langen Serien oder im Mehrschichtbetrieb deutlich bemerkbar macht.

Komplexe Bauteile erfordern oft den Einsatz mehrerer Werkzeuge, um die geforderte Geometrie und Oberflächenqualität zu erzielen. Ein automatischer Werkzeugwechsler (ATC) ermöglicht die Verwendung all dieser Werkzeuge in einem einzigen Bearbeitungszyklus und unterstützt so fortschrittlichere und effizientere Bearbeitungsstrategien.

Wenn Bediener mehrere CNC-Maschinen betreuen, werden manuelle Werkzeugwechsel zum Engpass. Ein automatischer Werkzeugwechsler reduziert den manuellen Eingriff und ermöglicht es einem Bediener, mehrere Maschinen effizient zu bedienen.

In Anwendungen, in denen Konsistenz und Wiederholgenauigkeit entscheidend sind, reduziert der automatisierte Werkzeugwechsel die durch manuelle Handhabung verursachten Abweichungen. Dies ist besonders wertvoll für Präzisionsteile und die langfristige Produktionsstabilität.

Welche CNC-Maschinentypen verwenden automatische Werkzeugwechsler?

Automatische Werkzeugwechsler sind am häufigsten an CNC-Bearbeitungszentren zu finden, darunter Vertikal-, Horizontal- und 5-Achs-Maschinen. Sie werden auch an einigen anderen Maschinen eingesetzt. CNC-Bohr- und Gewindeschneidmaschinen wenn mehrere Werkzeuge in einem Arbeitsgang benötigt werden.

Wie viele Werkzeuge kann ein automatischer Werkzeugwechsler aufnehmen?

Das hängt von der Maschinenkonstruktion ab.

Kleinere Maschinen können fasst 12–24 Werkzeugewährend größere Bearbeitungszentren Unterstützung 40, 60, oder sogar noch mehr. Bei der richtigen Kapazität geht es nicht darum, die meisten Werkzeuge zu haben – sondern darum, genug für Ihre typischen Aufgaben zu haben.

Verbessert ein automatischer Werkzeugwechsler die Bearbeitungsgenauigkeit oder nur die Geschwindigkeit?

Beides – aber auf unterschiedliche Weise.

Ein automatischer Werkzeugwechsler (ATC) verändert die Schnittgenauigkeit nicht von selbst, verbessert aber die Positioniergenauigkeit beim Werkzeugwechsel. Durch die Reduzierung manueller Eingriffe trägt er zu einer stabilen Werkzeugausrichtung bei, was wiederum eine höhere Bearbeitungsgenauigkeit insgesamt ermöglicht – insbesondere bei mehrstufigen Prozessen.

Ist ein automatischer Werkzeugwechsler für die Kleinserienfertigung notwendig?

Nicht immer.

Bei sehr kleinen Losgrößen oder einfachen Bearbeitungsvorgängen mit wenigen Werkzeugwechseln kann ein manueller Werkzeugwechsel ausreichend sein. Wenn jedoch auch kleine Losgrößen mehrere Werkzeuge erfordern oder komplexe Bearbeitungsprozesse durchgeführt werden, kann ein automatischer Werkzeugwechsler (ATC) Zeit sparen und Rüstunterbrechungen reduzieren.

Wie wirkt sich ein automatischer Werkzeugwechsler (ATC) auf die Maschinenwartung aus?

Ein automatischer Werkzeugwechsler (ATC) benötigt zusätzliche Komponenten, die regelmäßige Wartung erfordern, wie z. B. Reinigung, Inspektion und korrekte Werkzeugbestückung. Bei ordnungsgemäßer Wartung sind moderne ATC-Systeme zuverlässig und erhöhen den Wartungsaufwand nicht wesentlich.

Automatische Werkzeugwechsler verändern nicht die Art und Weise, wie Sie schneiden – sie verändern, wie reibungslos der Prozess abläuft.

Bei Bearbeitungen mit häufigen Werkzeugwechseln oder mehreren Arbeitsgängen sorgt ein automatischer Werkzeugwechsler (ATC) für einen kontinuierlichen Maschinenbetrieb. In einfacheren Bearbeitungsumgebungen kann ein manueller Werkzeugwechsel weiterhin sinnvoll sein. Letztendlich hängt es von der Art der Teilebearbeitung und der Struktur Ihres Arbeitsablaufs ab.

Wenn Sie nach Möglichkeiten suchen, Unterbrechungen zu reduzieren oder Ihren Bearbeitungsprozess zu optimieren, ist die Überprüfung Ihres Werkzeugwechsel-Workflows ein guter Ausgangspunkt. In vielen Fällen ist ein kurze Diskussion über die Anwendung Es genügt, um zu prüfen, ob ein automatischer Werkzeugwechsler geeignet ist – oder ob eine andere Konfiguration besser funktionieren würde.