Nutfräsen ist eines der am häufigsten eingesetzten CNC-Bearbeitungsverfahren zur Herstellung präziser Nuten, Rillen und Keilnuten in Bauteilen der Automobil-, Luft- und Raumfahrt-, Formenbau- und allgemeinen Maschinenbauindustrie. Ob Aluminium, Edelstahl oder gehärteter Stahl – die Ergebnisse hängen maßgeblich von der Wahl des richtigen Nutfräsers, Vollhartmetall-Schaftfräsers, Wendeschneidplattenfräsers und eines stabilen CNC-Bearbeitungszentrums ab. Mit den richtigen Schnittparametern, Werkzeugwegstrategien und der erforderlichen Maschinenstabilität lassen sich beim Nutfräsen engere Toleranzen, glattere Oberflächen und längere Werkzeugstandzeiten erzielen. In diesem Leitfaden erfahren Sie mehr über Nutfräswerkzeuge, Bearbeitungstechniken, Lösungen zur Fehlerbehebung und wie moderne CNC-Maschinen – wie die vertikalen Bearbeitungszentren von Yangsen und 5-Achs-Bearbeitungssysteme – überlegene Leistung und Konsistenz beim Nutfräsen gewährleisten.

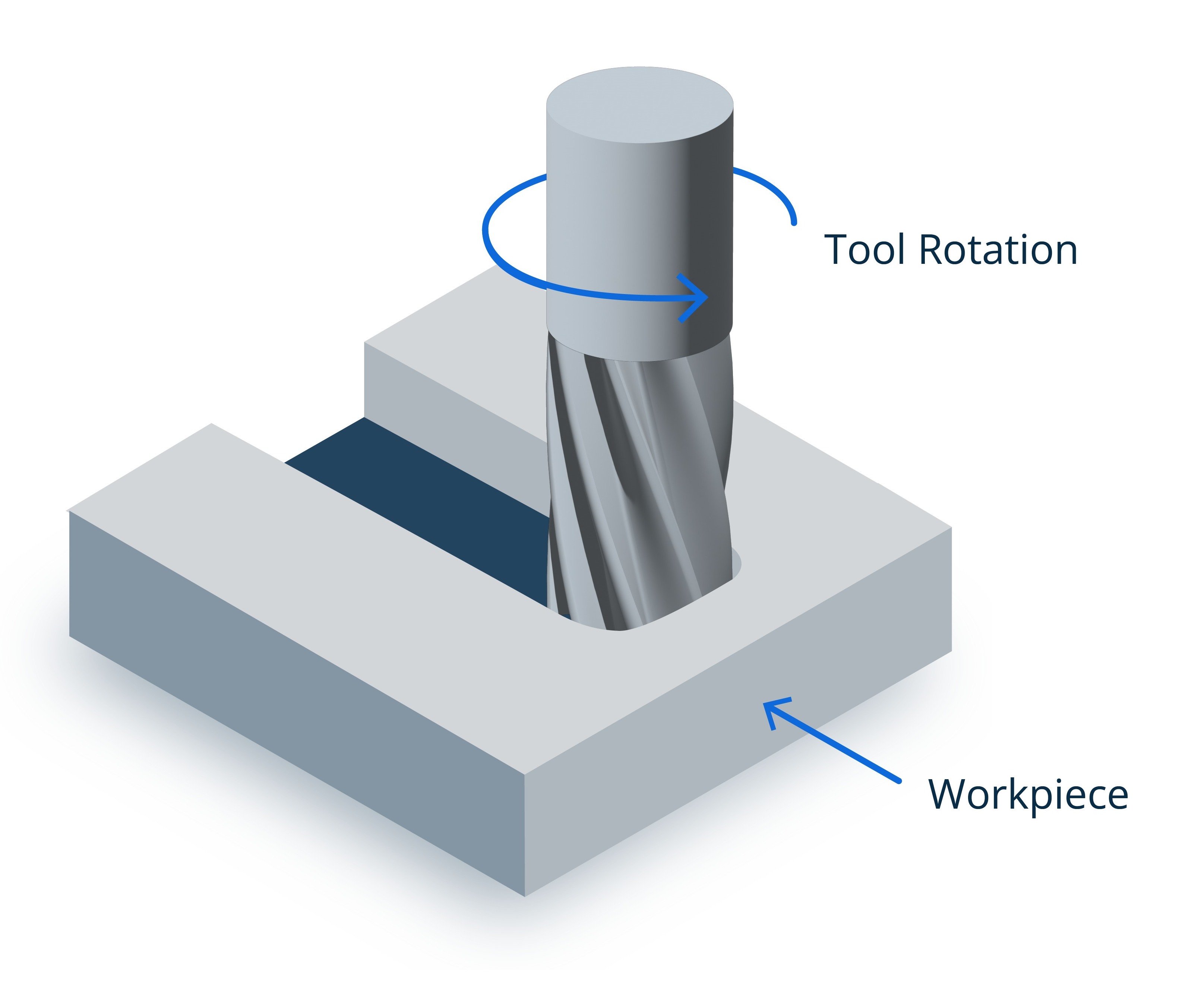

Nutfräsen ist ein Bearbeitungsverfahren, bei dem Material abgetragen und eine Nut, einen Kanal oder eine Keilnut an einem Werkstück erzeugt wird. CNC-FräsmaschineIm Gegensatz zum Plan- oder Seitenfräsen greift beim Nutenfräsen die gesamte Breite des Fräsers in das Material ein, sodass das Werkzeug während des Schnitts vollständig von Material umgeben ist. Dies stellt höhere Anforderungen an die Werkzeugsteifigkeit, die Spanabfuhr und die Bearbeitungsstabilität.

Nuten können je nach Anwendungsanforderung in Tiefe, Breite und Geometrie variieren. Gängige Typen sind Keilnuten für Wellen, T-Nuten für Maschinenvorrichtungen, Sacknuten und tiefe, schmale Präzisionsnuten, die häufig in Formen und Bauteilen der Luft- und Raumfahrtindustrie zu finden sind. Das Nutenfräsen wird häufig bei Teilen eingesetzt, die Ausrichtungs-, Bewegungssteuerungs- oder mechanische Verriegelungsfunktionen erfordern.

Da sich verschiedene Werkstoffe unter Schnittkräften unterschiedlich verhalten, hängt die Erzielung von Genauigkeit von der Auswahl des richtigen Nutfräsers, Vollhartmetall-Schaftfräsers oder Wendeschneidplattenwerkzeugs sowie der Anwendung der korrekten Schnittgeschwindigkeit, des Vorschubs und der Werkzeugwegstrategie ab. Bei korrekter Ausführung ermöglicht das Nutfräsen Herstellern die Einhaltung hoher Maßtoleranzen und eine gleichbleibende Wiederholgenauigkeit, insbesondere auf einem stabilen und steifen CNC-Bearbeitungszentrum oder einer 5-Achs-Bearbeitungsanlage.

Die Wahl des richtigen Schneidwerkzeugs ist einer der wichtigsten Faktoren für präzises und effizientes Nutenfräsen. Unterschiedliche Nutformen, Materialhärten und Bearbeitungsbedingungen erfordern unterschiedliche Fräsergeometrien und Werkzeugmaterialien. Zu den gängigsten Werkzeuglösungen für das Nutenfräsen zählen Vollhartmetall-Schaftfräser, Wendeschneidplattenfräser und spezielle Nutenfräser wie Keilnut- und T-Nutenfräser.

Vollhartmetall-Schaftfräser Sie eignen sich ideal für das hochpräzise Nutenfräsen in härteren Werkstoffen wie Edelstahl, legiertem Stahl und Titan. Sie bieten hervorragende Steifigkeit, Verschleißfestigkeit und Oberflächengüte und sind daher ideal für tiefe und schmale Nuten, bei denen Maßgenauigkeit entscheidend ist. Für die Hochgeschwindigkeitsbearbeitung oder das Nutenfräsen von Aluminium verbessern Mehrschneider-Hartmetallwerkzeuge mit polierten Schneiden oder DLC-Beschichtung die Spanabfuhr und reduzieren die Aufbauschneidenbildung.

Für die Bearbeitung dickerer Werkstoffe oder großer Nutabmessungen bieten Wendeschneidplattenfräser eine höhere Wirtschaftlichkeit. Diese Fräser ermöglichen einen einfachen Wendeschneidplattenwechsel ohne Nachschleifen oder Austausch des gesamten Werkzeugkörpers und eignen sich daher ideal für Langzeitproduktionen. Wendeschneidplattengeometrie und Beschichtungen wie TiN, TiAlN oder AlTiN können je nach Werkstückmaterial und Schnittgeschwindigkeit ausgewählt werden.

Manche Nutkonstruktionen erfordern Spezialwerkzeuge wie Keilnutfräser, Trennsägen und T-Nutfräser, insbesondere im Vorrichtungsbau, Formenbau und der Fertigung von Maschinenbauteilen. Diese Werkzeuge sind für die Herstellung von nicht standardisierten Nutprofilen mit hoher Wiederholgenauigkeit ausgelegt.

Die korrekte Einstellung der Bearbeitungsparameter ist entscheidend für ein stabiles Ergebnis beim Nutenfräsen, minimalen Werkzeugverschleiß und die Einhaltung der Maßgenauigkeit. Da beim Nutenfräsen häufig die gesamte Werkzeugbreite im Eingriff ist, sind die Schnittkräfte im Vergleich zum Seitenfräsen oder leichten Schruppen höher. Daher müssen Bediener Spindeldrehzahl, Vorschub, Schnitttiefe und Kühlmittelstrategie sorgfältig an Werkzeugtyp und Material anpassen.

Die Spindeldrehzahl (U/min) sollte anhand der Schnittgeschwindigkeit (Vc), des Werkzeugdurchmessers und der Werkstoffhärte bestimmt werden. Härtere Werkstoffe wie Edelstahl oder Werkzeugstahl erfordern niedrigere Drehzahlen, um übermäßige Wärmeentwicklung zu vermeiden, während weichere Werkstoffe wie Aluminium mit höheren Drehzahlen bearbeitet werden können, insbesondere mit Vollhartmetall-Schaftfräsern, die für die Hochgeschwindigkeitsbearbeitung ausgelegt sind.

Der Vorschub pro Zahn (fz) hat entscheidenden Einfluss auf die Spandicke. Ein zu geringer Vorschub kann Reibung statt Schnitt verursachen und so vorzeitigen Verschleiß oder eine schlechte Oberflächengüte zur Folge haben. Ein zu hoher Vorschub kann das Werkzeug überlasten und zu Rattern oder Nutverformungen führen. Beim Nutenfräsen trägt ein moderater Vorschub mit gleichmäßiger Spanbelastung dazu bei, die Werkzeugstandzeit und die Bearbeitungsstabilität zu gewährleisten.

Die Schnitttiefe (ap) und die Zustellung (ae) müssen in Abhängigkeit von der Werkzeugsteifigkeit und den Maschineneigenschaften angepasst werden. Für einen vollständigen Eingriff in die Nut sind in der Regel konservative Tiefeneinstellungen erforderlich, insbesondere bei der Bearbeitung tiefer oder schmaler Nuten. Progressive Nutenfräsverfahren oder trochoidale Verfahren können angewendet werden, wenn eine größere Nuteneindringtiefe erforderlich ist.

Eine effektive Kühlung und Späneabfuhr sind beim Nutenfräsen, insbesondere bei Sacknuten, unerlässlich. Flutkühlung, Druckluft und gegebenenfalls Minimalmengenschmierung (MMS) können Spanbildung, Überhitzung und Werkzeugbruch verhindern. Bei Aluminium und zähflüssigen Werkstoffen kann eine Hochdruckkühlung oder eine polierte Nutengeometrie die Spankontrolle deutlich verbessern.

Optimale Bearbeitungsparameter ermöglichen eine gleichmäßige Nutbreite, bessere Oberflächengüten und längere Werkzeugstandzeiten. In Kombination mit einem stabilen vertikalen Bearbeitungszentrum oder einer 5-Achs-CNC-Maschine wird das Nutfräsen kontrollierter, wiederholgenauer und effizienter – für verschiedene Materialien und Anwendungen.

Erfolgreiches Nutenfräsen erfordert mehr als die Auswahl des richtigen Werkzeugs und die Einstellung grundlegender Parameter – es hängt auch von der Wahl der optimalen Bearbeitungsstrategie ab. Da der Fräser vollständig im Material im Eingriff ist, sind die Steuerung von Wärme, Schnittkraft und Spanabfuhr entscheidend für die Genauigkeit und die Werkzeugstandzeit.

Eine der effektivsten Methoden zum Nutenfräsen ist das Gleichlauffräsen, bei dem sich der Fräser in Vorschubrichtung dreht. Dieses Verfahren reduziert den Schnittdruck, erzeugt glattere Oberflächen und minimiert die Gratbildung. Konventionelles Fräsen sollte nur in Ausnahmefällen eingesetzt werden, beispielsweise bei der Bearbeitung instabiler Werkstücke oder Gussoberflächen.

Bei tiefen oder schmalen Nuten verbessert eine progressive Nutenbearbeitungsstrategie die Stabilität. Anstatt die volle Tiefe in einem Arbeitsgang abzufräsen, vertieft das Werkzeug die Nut schrittweise bei gleichbleibender Spanabfuhr. Dieses Verfahren reduziert Vibrationen und verhindert Werkzeugdurchbiegungen – besonders vorteilhaft bei der Verwendung von Vollhartmetall-Schaftfräsern mit kleinem Durchmesser.

Fortschrittliche Werkzeugwege wie das Trochoidalfräsen oder das adaptive Freischneiden werden zunehmend für die Nutenbearbeitung eingesetzt. Diese Verfahren gewährleisten einen konstanten Eingriff und minimieren die Radialbelastung des Werkzeugs. Sie ermöglichen höhere Vorschubgeschwindigkeiten, reduzieren die Wärmeentwicklung und verlängern die Werkzeugstandzeit deutlich, wodurch sie sich ideal für harte Werkstoffe wie Edelstahl, Inconel oder gehärteten Werkzeugstahl eignen.

Hochgeschwindigkeitsbearbeitung (HSM) kann auch beim Nutenfräsen Vorteile bieten, wenn sie durch ein stabiles CNC-Bearbeitungszentrum mit hochpräziser Spindel und einem robusten Werkzeughaltersystem (BT40, HSK-A63 oder CAT40) unterstützt wird. Die Kombination aus geringer Zustellung und hohen Vorschubgeschwindigkeiten ermöglicht eine gleichmäßige Nutenerzeugung bei kontrollierter Wärmeentwicklung.

Schließlich darf eine effektive Spanabfuhr nicht vernachlässigt werden. Sacknuten und tiefe Rillen erfordern Kühlmittel, Druckluft oder Minimalmengenschmierung, um zu verhindern, dass sich Späne in der Nut ansammeln, was zu Brüchen, Überbreite oder Oberflächenbeschädigungen führen kann.

Nutfräsen findet in vielen Fertigungsbranchen breite Anwendung, wo präzise Nuten, Keilnuten und mechanische Eingriffselemente benötigt werden. Da Nuten häufig die Ausrichtung, Montage und Lastübertragung beeinflussen, sind Genauigkeit und Wiederholgenauigkeit von entscheidender Bedeutung. Im Folgenden sind die gängigsten Branchen aufgeführt, die Nutfräsen einsetzen:

Wird zur Bearbeitung von Getriebewellen, Zahnradkomponenten, Motorgehäusen und Strukturteilen verwendet.

Gängige Nuttypen sind Keilnuten, Ausrichtungsnuten und funktionelle Montagenuten.

Bei der Serienfertigung werden häufig Wendeschneidplattenfräser eingesetzt, um Kosteneffizienz und gleichbleibende Präzision zu gewährleisten.

Anforderungen: enge Toleranzen, Wiederholgenauigkeit und stabile Zykluszeiten.

Anwendung findet dies bei leichten Strukturbauteilen, Halterungen, Kraftstoffsystemteilen, Motoraufhängungen und Bewegungsmechanismen.

Zu den Werkstoffen gehören häufig Aluminiumlegierungen, Titan und hitzebeständige Superlegierungen.

Für die Bearbeitung wird typischerweise eine hohe Bearbeitungsgeschwindigkeit mit Vollhartmetall-Schaftfräsern und optimierten Werkzeugwegen benötigt.

Kritische Prioritäten: hohe Steifigkeit, Oberflächenqualität und kontrollierte thermische Verformung.

Wird zur Bearbeitung von Kühlkanälen, Führungsnuten, tiefen, schmalen Nuten und präzisen Formteilen verwendet.

Zu den Werkstoffen gehören vorgehärteter Stahl, gehärteter Werkzeugstahl und hochlegierte Formblöcke.

5-Achs-Bearbeitungszentren und hochpräzise vertikale Bearbeitungszentren werden üblicherweise bevorzugt.

Erfordert eine ausgezeichnete Maßhaltigkeit und eine glatte Oberflächenbeschaffenheit, um die Nachbearbeitung zu minimieren.

Das Nutenfräsen ist unerlässlich für T-Nut-Tische, Führungsschienen, mechanische Platten, Gehäuse und Vorrichtungsbauteile.

Da die Werkstücke oft groß sind, sind Steifigkeit und Maschinenstabilität von entscheidender Bedeutung.

Für eine effiziente Bearbeitung werden häufig Wendeschneidplatten-Nutfräser und Keilnutfräser eingesetzt.

Schwerpunkt: Langlebigkeit, Bearbeitungsflexibilität und Kompatibilität mit großformatigen CNC-Maschinen.

Anwendung findet es in Vorrichtungen, Spannsystemen, Steckverbindern, Teilen für medizinische Geräte, Roboterkomponenten und Präzisionsgehäusen.

Kleinserienfertigung und kundenspezifische Anpassungen machen mehrachsige CNC-Bearbeitungszentren zur idealen Lösung.

Oberflächenbeschaffenheit und Maßtoleranzen sind von entscheidender Bedeutung, insbesondere bei Bauteilen für die Montage.

1. Welches Werkzeug eignet sich am besten zum Nutenfräsen?

Das beste Werkzeug hängt vom Material und den Nutabmessungen ab. Vollhartmetall-Schaftfräser eignen sich ideal für Präzisionsarbeiten und härtere Werkstoffe, während Wendeschneidplattenfräser für große Nutbreiten oder die Serienfertigung bevorzugt werden.

2. Kann das Fräsen von Nuten auf jeder CNC-Maschine durchgeführt werden?

Nutfräsen ist auf den meisten CNC-Fräsmaschinen möglich, Genauigkeit und Stabilität hängen jedoch von der Maschinensteifigkeit ab. Für optimale Ergebnisse empfiehlt sich ein vertikales Bearbeitungszentrum oder eine 5-Achs-CNC-Maschine mit BT40- oder HSK-Werkzeugaufnahme.

3. Wie kann ich Werkzeugbruch beim Nutenfräsen tiefer Nuten vermeiden?

Verwenden Sie progressive Schnitttiefen, reduzieren Sie den radialen Eingriff, setzen Sie Kühlmittel oder Druckluft zur Spanabfuhr ein und vermeiden Sie übermäßigen Werkzeugüberstand. Trochoidale oder adaptive Werkzeugwege tragen ebenfalls zur Reduzierung der Belastung bei.

4. Welche Schnittparameter werden für das Nutenfräsen empfohlen?

Beginnen Sie mit einem moderaten Vorschub pro Zahn (fz) und reduzieren Sie die Schnitttiefe (ap) bei vollem Eingriff in die Nut. Die Schnittgeschwindigkeit sollte sich nach Werkstückmaterial, Beschichtungsart und Spindelleistung richten.

5. Wie kann ich die Oberflächengüte beim Nutenfräsen verbessern?

Verwenden Sie Gleichlauffräsen, reduzieren Sie Rattern durch Verkürzen des Werkzeugvorschubs, führen Sie einen Schlichtgang mit reduziertem Vorschub durch und achten Sie auf eine ausreichende Kühlmittelzufuhr. Höhere CNC-Steifigkeit und Präzisionswerkzeughalter verbessern ebenfalls die Oberflächenqualität.

6. Warum ist die Schlitzbreite manchmal zu groß?

Zu große Nuten entstehen meist durch Werkzeugdurchbiegung, Rattern oder eine fehlerhafte Werkzeugwegstrategie. Durch Reduzierung der Schnitttiefe, Erhöhung der Maschinensteifigkeit und Optimierung der Vorschubgeschwindigkeit lässt sich das Problem beheben.

Das Nutenfräsen ist ein entscheidender Bearbeitungsprozess in Branchen, die präzise Nuten, Keilnuten und Strukturkanäle benötigen. Von der Werkzeugauswahl bis zur Bearbeitungsstrategie beeinflusst jedes Detail – wie Vorschubgeschwindigkeit, Spindeldrehzahl, Fräsergeometrie und Spanabfuhr – direkt Genauigkeit, Oberflächengüte und Produktivität. Mit den richtigen Werkzeugen, Schnittparametern und softwaregesteuerten Werkzeugwegen wird das Nutenfräsen für unterschiedliche Materialien und Bauteilkomplexitäten berechenbarer, effizienter und wiederholgenauer.

Der Erfolg beim Nutenfräsen hängt jedoch nicht allein vom Werkzeug ab, sondern ebenso von der dahinterstehenden Maschine. Ein hochsteifes CNC-Bearbeitungszentrum mit stabiler Spindel, präzisem Werkzeughaltersystem und effektiver Schwingungsdämpfung kann die Nutgeometrie, die Toleranzstabilität und die Werkzeugstandzeit deutlich verbessern. Daher ist die Wahl der richtigen Maschine genauso wichtig wie die Wahl des richtigen Fräsers.

Bei Yangsen CNC entwickeln und fertigen wir CNC-Bearbeitungszentren speziell für hochpräzise Fräsanwendungen – darunter Nutfräsen, Keilnutfräsen, Formbearbeitung und mehrachsiges Konturfräsen. Unsere 3-Achs-Vertikalbearbeitungszentren und 5-Achs-CNC-Lösungen zeichnen sich durch hohe Steifigkeit, thermische Stabilität und Genauigkeit aus und eignen sich daher für Branchen von der Luft- und Raumfahrt über die Automobilindustrie bis hin zum Formenbau und der Hochpräzisionsbearbeitung.