Moderne Fertigungsindustrien stehen vor großen Herausforderungen bei der Erzielung hoher Präzision und Effizienz bei der Bewältigung komplexer Bearbeitungsaufgaben. Herkömmliche Fräsmaschinen sind bei der Bearbeitung großformatiger oder komplizierter Bauteile oft unzureichend, was die Produktionszeit und -kosten erhöht.

Portal-CNC-Fräsmaschinen bietet eine wirksame Lösung für diese Probleme. Sie sind auf Präzision und Vielseitigkeit ausgelegt und können große und schwere Werkstücke mit hoher Genauigkeit bearbeiten. Ihre fortschrittlichen Automatisierungsfunktionen und Mehrachsenfähigkeiten verbessern die Produktivität und reduzieren menschliche Fehler.

Portal-CNC-Fräsmaschinen sind in der Luft- und Raumfahrt-, Automobil- und Schwermaschinenindustrie durch die Integration robuster Konstruktion, innovativer Steuerungssysteme und modernster Software unverzichtbar geworden. Diese Maschinen verändern Fertigungsprozesse und ermöglichen es Unternehmen, moderne Anforderungen mit höchster Qualität und Effizienz zu erfüllen.

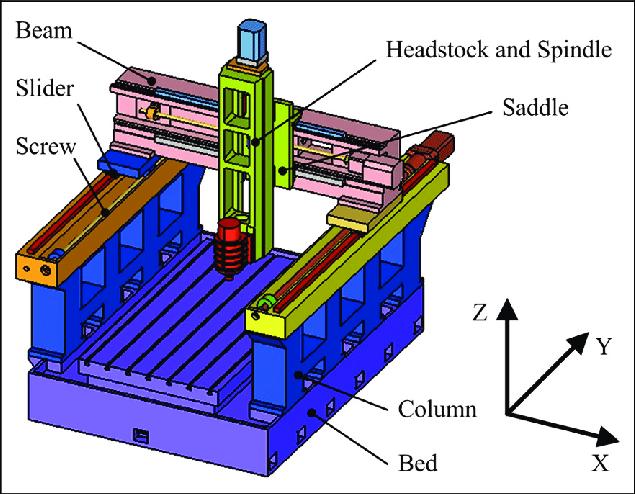

Portalstruktur

Es bildet den Hauptrahmen der Maschine, bietet Halt und Stabilität für präzise Arbeiten und bestimmt die Fähigkeit der Maschine, schwere Lasten zu handhaben.

Brücke, Säulen und Basis

Die Brücke überspannt die Portalkonstruktion, während die Säulen und der Sockel für ein solides Fundament sorgen. Zusammen minimieren sie die Verformung während der Bearbeitung.

Schneidwerkzeug und Spindelbaugruppe

Die Spindel dreht das Schneidwerkzeug mit unterschiedlichen Geschwindigkeiten und ermöglicht so einen präzisen Materialabtrag. Diese Komponente hat direkten Einfluss auf die Präzision und Effizienz der Bearbeitung.

Steuerungssysteme und Software

Fortschrittliche Systeme verwalten mehrachsige Bewegungen und optimieren den Betrieb. Die Softwareintegration ermöglicht eine präzise Programmierung und Anpassungen in Echtzeit.

Festes Portal

Das Portal bleibt stationär, während sich der Arbeitstisch bewegt. Geeignet für kleine bis mittelgroße Werkstücke, die eine hohe Präzision erfordern.

Bewegliches Portal

Das Portal bewegt sich, während der Arbeitstisch fest bleibt. Ideal für die Handhabung größerer Werkstücke mit größerer betrieblicher Flexibilität.

Hybride Designs

Es kombiniert die Merkmale fester und beweglicher Portale, um Präzision und Anpassungsfähigkeit in Einklang zu bringen. Diese Designs werden in speziellen Anwendungen verwendet.

3-Achsen-Systeme

Führen Sie grundlegende Bearbeitungsaufgaben wie Bohren, Fräsen und Konturieren aus. Es eignet sich für einfachere Designs und weniger komplexe Geometrien.

5-Achsen-Systeme

Sie bieten eine erhöhte Flexibilität für komplizierte Maschinenteile. Sie ermöglichen eine gleichzeitige Bewegung entlang fünf Achsen für hohe Präzision und komplexe Formen.

• Große Tische bieten Platz für größere Werkstücke, ideal für die Fertigung im industriellen Maßstab.

• Einstellbare Tischgrößen helfen dabei, den spezifischen Anforderungen verschiedener Anwendungen gerecht zu werden.

• Die erhöhte Kapazität gewährleistet die Unterstützung schwerer Materialien ohne Kompromisse bei der Genauigkeit.

• Hochleistungsspindeln ermöglichen die Bearbeitung von zähen Materialien wie Stahl oder Titan.

• Die einstellbaren Spindeldrehzahlen erfüllen unterschiedliche Schneidanforderungen und sorgen für optimale Ergebnisse.

• Eine konstante Leistung verbessert die Effizienz und reduziert den Verschleiß der Werkzeuge.

• Maschinen halten enge Toleranzen ein, um eine gleichbleibende Produktionsqualität zu gewährleisten.

• Die Wiederholbarkeit gewährleistet die Genauigkeit über mehrere Zyklen hinweg, was für die Massenproduktion von entscheidender Bedeutung ist.

• Dank der verbesserten Präzision können komplexe Designs mit minimalen Fehlern erstellt werden.

Werkzeugwechsler

• Wechseln Sie die Werkzeuge während des Betriebs automatisch, um Zeit zu sparen und die Effizienz zu verbessern.

• Reduzieren Sie den Bedarf an manuellen Eingriffen und verbessern Sie so den Arbeitsablauf.

Sondierungssysteme

• Ermöglichen Sie die Echtzeitmessung von Werkstücken zur Ausrichtung und Fehlererkennung.

• Verbessern Sie die Prozesskontrolle und reduzieren Sie Abfall.

Integrierte Kühlung und Schmierung

• Sorgen Sie während der Bearbeitung für optimale Werkzeugtemperaturen.

• Reduzieren Sie den Werkzeugverschleiß und verbessern Sie die Materialabtragsraten.

• Fortschrittliche Software vereinfacht die Programmierung komplexer Vorgänge.

• Die Integration ermöglicht die Kompatibilität mit CAD/CAM-Systemen für nahtlose Arbeitsabläufe vom Entwurf bis zur Produktion.

• Echtzeitüberwachung und -anpassungen verbessern die Maschinenleistung und gewährleisten die Zuverlässigkeit.

Kompakte Portalmühlen für kleine Anwendungen

• Entwickelt für kleinere Werkstücke und beengte Platzverhältnisse.

• Wird häufig in Werkstätten und Kleinindustrien eingesetzt, wo es auf Präzision ankommt.

• Kostengünstig und ideal für die Herstellung komplexer Bauteile.

Großformatige Portalmühlen für den industriellen Einsatz

• Gebaut für die Handhabung massiver Werkstücke und schwere Bearbeitungsaufgaben.

• Wird in Branchen eingesetzt, die große Strukturkomponenten erfordern, wie z. B. in der Luft- und Raumfahrt und im Schwermaschinenbau.

• Diese Maschinen bieten erweiterte Tischgrößen und höhere Tragfähigkeiten für die Fertigung im industriellen Maßstab.

Luft- und Raumfahrt

• Portal-CNC-Fräsmaschinen sind für die Herstellung hochpräziser Teile wie Flügelkomponenten und Turbinenschaufeln unerlässlich.

• Ihre Fähigkeit, große und komplexe Geometrien zu handhaben, gewährleistet die Qualität und Zuverlässigkeit, die in Luft- und Raumfahrtanwendungen erforderlich sind.

Automobil

• Wird häufig zur Bearbeitung von Motorblöcken, Formen und anderen kritischen Teilen verwendet.

• Ihre Mehrachsenfähigkeiten unterstützen schnellere Produktionszyklen und reduzieren Werkzeugwechsel.

Schwere Maschinen

• Ideal für die Herstellung langlebiger und großer Maschinenteile wie Zahnräder und Strukturrahmen.

• Die Maschinen sind so konstruiert, dass sie hohen Schnittkräften standhalten und gleichzeitig die Genauigkeit beibehalten.

Formen- und Formenbau

• Wird zur Herstellung von Formen für Kunststoffe und Stempeln zum Prägen verwendet.

• Ihre Präzision gewährleistet die Herstellung komplexer Formen und feiner Details mit minimalen Fehlern.

Materialverladung

Das Rohmaterial wird mittels Klammern oder Vorrichtungen sicher auf dem Maschinentisch platziert.

Die richtige Ausrichtung sorgt für Stabilität und verhindert ein Verrutschen während der Bearbeitung.

Programmierung und Einrichtung

Basierend auf den Konstruktionsvorgaben werden CNC-Programme erstellt CAD/CAM-Software.

Das Programm wird in das Steuerungssystem geladen und die Maschine wird für genaue Abläufe kalibriert.

Schneid- und Fräsarbeiten

Die Maschine führt programmierte Bewegungen aus, um das Material zu schneiden, zu formen oder zu fräsen.

Mehrachsfunktionen ermöglichen die präzise Bearbeitung komplexer Geometrien in einer einzigen Aufspannung.

Qualitätskontrolle und Endbearbeitung

Nach der Bearbeitung wird das Werkstück vermessen und auf Genauigkeit überprüft.

Um Glätte und Qualität zu gewährleisten, können zusätzliche Nachbearbeitungsprozesse wie Polieren oder Entgraten angewendet werden.

Planfräsen

Bei diesem Verfahren wird Material von der Oberfläche des Werkstücks entfernt, um eine ebene, glatte Oberfläche zu erzielen.

Es wird üblicherweise zum Nivellieren und Vorbereiten des Materials für die weitere Bearbeitung verwendet.

Konturfräsen

Umfasst das Schneiden entlang eines bestimmten Pfads, um gekrümmte Formen oder Profile zu erstellen.

Nützlich für die Bearbeitung von Teilen mit komplexen Geometrien, wie z. B. Formen und Matrizen.

Schlitzschneiden

Erzeugt schmale Rillen oder Schlitze im Material, häufig zu Montagezwecken.

Erfordert Präzision, um sicherzustellen, dass die Schlitze nahtlos in andere Komponenten passen.

`

Luft- und Raumfahrtindustrie

Wird für die Bearbeitung großer und komplexer Komponenten wie Flügelteile und Turbinenschaufeln verwendet.

Die Präzision und die Mehrachsenfähigkeit erfüllen die hohen Anforderungen in der Luft- und Raumfahrtfertigung.

Automobilindustrie

Unverzichtbar für die Herstellung von Formen, Motorblöcken und anderen wichtigen Fahrzeugteilen.

Portal-CNC-Fräsmaschinen unterstützen schnelle Produktionszyklen und sorgen für eine gleichbleibende Genauigkeit.

Schwere Maschinen und Geräte

Ideal für die Herstellung langlebiger Teile wie Strukturrahmen, Zahnräder und Maschinengehäuse.

Diese Mühlen verarbeiten schwere Materialien und bieten eine hohe Zuverlässigkeit für Großbetriebe.

Formen- und Formenbau

Wird häufig zur Herstellung von Formen für Kunststoffe und Matrizen für Stanzanwendungen verwendet.

Die Maschinen zeichnen sich durch die Erstellung komplexer Formen mit hoher Maßgenauigkeit aus.

Große Strukturbauteile

Portal-CNC-Fräsmaschinen fertigen große Komponenten für Brücken, Gebäude und Industrieanlagen.

Ihre Fähigkeit, schwere und übergroße Werkstücke zu handhaben, gewährleistet eine hohe Präzision bei Strukturanwendungen.

Komplexe Formen- und Formenherstellung

Perfekt für die Herstellung von Formen und Matrizen, die in verschiedenen Branchen wie der Automobil- und Konsumgüterbranche eingesetzt werden.

Diese Projekte erfordern oft komplizierte Details und hervorragende Oberflächengüten, die Portal-CNC-Fräsmaschinen bieten.

Präzisionsbearbeitung für Luft- und Raumfahrtteile

Entscheidend für die Herstellung leichter und dennoch stabiler Komponenten wie Rumpfteile und Fahrwerksbaugruppen.

Die Maschinen ermöglichen enge Toleranzen und glatte Oberflächen, die für Hochleistungsanwendungen in der Luft- und Raumfahrt erforderlich sind.

Portal-CNC-Fräsmaschinen bieten außergewöhnliche Genauigkeit und ermöglichen die Herstellung von Teilen mit engen Toleranzen. Fortschrittliche Steuerungssysteme und Mehrachsenfähigkeiten sorgen für konsistente Ergebnisse und machen diese Maschinen für Branchen wie Luft- und Raumfahrt und Automobil unverzichtbar.

Portal-CNC-Fräsmaschinen sind mit robusten Strukturen ausgestattet und für die Bearbeitung übergroßer und schwerer Materialien ausgelegt. Große Arbeitstische tragen sperrige Komponenten und gewährleisten so eine hohe Leistung für Strukturteile und Schwermaschinenanwendungen.

Diese Maschinen vereinen mehrere Funktionen wie Bohren und Fräsen in einem System. Ihr mehrachsiges Design reduziert den Neupositionierungsbedarf, spart Zeit und sorgt für Effizienz im Produktionsprozess.

Automatisierte Funktionen wie Werkzeugwechsler und Hochgeschwindigkeitsspindeln verbessern die Bearbeitungseffizienz. Portal-CNC-Fräsmaschinen steigern die Produktivität und beschleunigen Produktionszyklen, indem sie manuelle Eingriffe und Ausfallzeiten minimieren.

Portal-CNC-Fräsmaschinen können verschiedene Materialien bearbeiten, darunter Metalle, Kunststoffe und Verbundwerkstoffe. Aufgrund dieser Anpassungsfähigkeit eignen sie sich für verschiedene Branchen, von leichten Teilen für die Luft- und Raumfahrt bis hin zu schweren Stahlkomponenten.

Geschlossene Arbeitsbereiche und integrierte Sicherheitsfunktionen schützen den Bediener vor Gefahren. Ergonomische Bedienelemente vereinfachen die Maschinenbedienung, sorgen für eine sicherere und komfortablere Arbeitsumgebung und verbessern gleichzeitig die Gesamteffizienz.

Künstliche Intelligenz und maschinelles Lernen verändern die CNC-Programmierung durch die Automatisierung komplexer Aufgaben. Diese Technologien analysieren Bearbeitungsmuster und optimieren Werkzeugwege für mehr Effizienz und Genauigkeit. Adaptive Systeme lernen aus früheren Vorgängen, reduzieren Programmierfehler und verbessern die Produktionsergebnisse.

Das Internet der Dinge (IoT) ermöglicht die Datenerfassung und -überwachung in Echtzeit in Portal-CNC-Fräsmaschinen. Sensoren überwachen die Maschinenleistung, erkennen Anomalien und senden Warnungen zur vorbeugenden Wartung. Dies minimiert Ausfallzeiten, erhöht die Betriebszuverlässigkeit und ermöglicht es Herstellern, eine gleichbleibende Produktionsqualität aufrechtzuerhalten.

Fortschrittliche Simulationssoftware ermöglicht es Bedienern, Bearbeitungsprozesse vor Produktionsbeginn zu visualisieren. Diese Tools helfen dabei, potenzielle Probleme zu erkennen, Werkzeugwege zu optimieren und Präzision sicherzustellen. Die verbesserte Softwareintegration unterstützt außerdem die nahtlose Kommunikation zwischen Design- und Produktionssystemen und verbessert so den gesamten Arbeitsablauf und die Genauigkeit.

Bei der Auswahl einer Portal-CNC-Fräse ist es von entscheidender Bedeutung, die spezifische Anwendung zu verstehen. Berücksichtigen Sie die Art der Werkstücke, die Sie bearbeiten möchten, beispielsweise große Strukturbauteile oder komplizierte Formen. Die Maschine sollte auf Ihre Produktionsanforderungen abgestimmt sein und Effizienz und Präzision im Betrieb gewährleisten.

Die Materialien, die Sie bearbeiten möchten, spielen eine wichtige Rolle bei der Auswahl der richtigen CNC-Fräse. Verschiedene Modelle sind für die Bearbeitung einer Vielzahl von Materialien konzipiert, von Metallen wie Stahl und Aluminium bis hin zu Verbundwerkstoffen und Kunststoffen. Die Sicherstellung der Materialkompatibilität trägt dazu bei, die Bearbeitungsqualität und die Langlebigkeit des Werkzeugs aufrechtzuerhalten.

Bewerten Sie die Präzisions- und Geschwindigkeitsanforderungen Ihres Produktionsprozesses. Wählen Sie eine Maschine mit fortschrittlichen Steuerungssystemen und hoher Wiederholgenauigkeit für Aufgaben, die enge Toleranzen erfordern. Ebenso sind hohe Spindelgeschwindigkeiten für einen effizienten Materialabtrag und schnellere Produktionszyklen unerlässlich.

Das Budget ist ein Schlüsselfaktor für die richtige Wahl. Vergleichen Sie Maschinen, die im Rahmen Ihrer finanziellen Möglichkeiten die erforderlichen Funktionen bieten. Während die Anschaffungskosten wichtig sind, sollten auch langfristige Einsparungen durch kürzere Produktionszeiten und geringeren Wartungsbedarf in Betracht gezogen werden.

Zuverlässiger Wartungs- und Servicesupport ist entscheidend für die Minimierung von Ausfallzeiten. Wählen Sie eine Maschine von einem Hersteller oder Lieferanten, der zugängliche technische Unterstützung und Ersatzteile bietet. Regelmäßige Wartungspläne und schneller Service können die Lebensdauer der CNC-Fräse verlängern und einen unterbrechungsfreien Betrieb gewährleisten.

Hybride Bearbeitungssysteme kombinieren additive und subtraktive Verfahren und erfreuen sich zunehmender Beliebtheit. Diese Systeme ermöglichen die Integration des 3D-Drucks mit dem herkömmlichen CNC-Fräsen und ermöglichen es Herstellern, Teile in einem einzigen Aufbau zu bauen und zu verfeinern. Dieser Ansatz reduziert Materialverschwendung, verkürzt Produktionszeiten und erhöht die Flexibilität bei der Handhabung komplexer Geometrien.

Mit dem technologischen Fortschritt finden Portal-CNC-Fräsmaschinen in neuen Branchen Anwendung. Sektoren wie erneuerbare Energien, Herstellung medizinischer Geräte und fortschrittliche Robotik beginnen, diese Maschinen einzusetzen. Ihre Fähigkeit, präzise Komponenten aus verschiedenen Materialien herzustellen, macht sie für neue Technologien und spezielle Produktionsanforderungen geeignet.

Dank verbesserter Erschwinglichkeit und kompakter Bauweise werden Portal-CNC-Fräsmaschinen auch für kleinere Unternehmen zugänglicher. Vereinfachte Schnittstellen und benutzerfreundliche Software reduzieren den Lernaufwand für Bediener und ermöglichen es KMU, CNC-Technologie in ihre Arbeitsabläufe zu integrieren. Diese Zugänglichkeit hilft kleineren Unternehmen, auf Märkten zu konkurrieren, die traditionell von großen Herstellern dominiert werden.

Portal-CNC-Fräsmaschinen sind in der modernen Fertigung von entscheidender Bedeutung, da sie Präzision, Vielseitigkeit und Effizienz bieten. Sie eignen sich hervorragend für die Handhabung großer und komplexer Werkstücke und sind daher unverzichtbar in der Luft- und Raumfahrt-, Automobil- und Schwermaschinenindustrie. Mit Fortschritten in Technologie und Automatisierung haben diese Maschinen die Bearbeitungsprozesse verändert und eine Anpassungsfähigkeit an verschiedene Materialien und Anwendungen gewährleistet. Die Erkundung hochwertiger Portal-CNC-Fräsmaschinen, die auf spezifische Anforderungen zugeschnitten sind, kann die Produktivität erheblich steigern und einen Wettbewerbsvorteil in der heutigen Industrielandschaft sichern.